Demand Forecasting Should Be a Core Competency

For many US manufacturers, the business landscape has changed dramatically over the past several years. Not only have we endured a downturn in the economy, causing increased competition, but we have been lured to the world of outsourced manufacturing. So the question becomes: Where should manufacturers that were more vertically integrated refocus and develop core competencies? Certainly brand management, quality and even culture are long standing core competencies, but what — from a process perspective — makes the biggest difference?

For many US manufacturers, the business landscape has changed dramatically over the past several years. Not only have we endured a downturn in the economy, causing increased competition, but we have been lured to the world of outsourced manufacturing. So the question becomes: Where should manufacturers that were more vertically integrated refocus and develop core competencies? Certainly brand management, quality and even culture are long standing core competencies, but what — from a process perspective — makes the biggest difference?

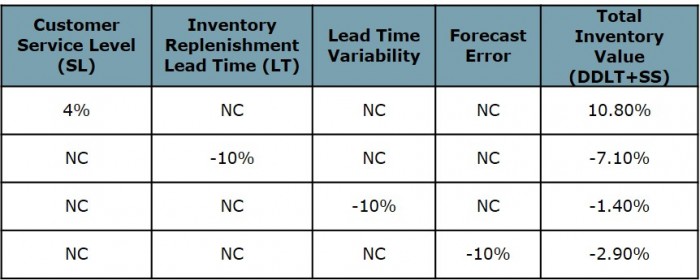

The answer is obviously different for different companies, but one central issue that applies to all is the ability to predict demand accurately. In many companies, demand forecasting is considered important but not important enough to work on improvement programs. The problem sometimes stems from a lack of understanding of how to improve forecast accuracy (or that it can be improved), as well as what the improvement is worth in profit and asset utilization. During a recent test with a consumer goods manufacturer, the following results were calculated:

Notice the obvious increase in inventory associated with customer service level improvements. In many cases, being able to rebalance or reclassify inventory as a result of improved forecast accuracy can produce significant improvements in customer service without increasing overall inventory value.

As with service levels, reducing lead time obviously produces a significant reduction in inventory. However, notice the not so obvious reduction in inventory if the lead time variability is improved.

Forecast accuracy improvements have little or no impact on this. Also notice in this case the 2.9% reduction in inventory resulting from a 10% improvement in forecast accuracy. This number is misleading because the consumer goods company in question had a longer lead time for the forecasted items.

If the demand during lead time (DDLT) is much smaller and the product item level forecasts are much worse in the beginning, then the impact of forecast improvements on reducing inventory would be much greater than shown here. Combine the direct reductions in safety stock with the ability to rebalance inventory, and the results can be dramatic.

Demand forecasting is a core competency for manufactures today especially if they have begun to outsource, which can potentially drive lead times up and flexibility down if item-level forecasts are not improved. The approach many manufactures have turned to is to implement an internal collaborative forecasting process driven from a more sophisticated bottoms-up statistical baseline forecasting approach. In today’s world of Supply Chain tools, users need only a rudimentary knowledge of data analysis and statistics and should be expected to primarily deal with exceptions to the forecasting process driven by predetermined business rules such as absolute forecast error or forecast bias.

By no means is demand forecasting a black box approach nor will it ever be, but the analytical heavy lifting can be done with software tools and the results can be measured to determine the trust to place in the process and when to use internal experts. In fact, measuring forecast accuracy at all levels of detail will, in and of itself, drive improvements. Surprisingly, few companies have reached this conclusion and made demand forecasting a core competency. Those companies that have are more competitive, more agile and more profitable.